A diversified farm plans its crop rotation around producing various perishable products that sell well, like tomatoes, peppers, and leafy greens. As the farm builds market opportunities, it might consider adding new or unusual crops to the crop plan. Storage crops can be part of that plan, extending the sale season for growers and additional value for customers. Storage crops might include winter squash, onions, and pumpkins. Another storage crop to consider is grain: flint corn, popcorn, wheat, or even dry edible beans, which are the focus of this article.

Stepping into the world of grain might seem daunting at first. The farmer might assume they need a lot of land, a combine harvester, large tractors, and complex planting equipment to ensure success. This project aims to dispel preconceived notions about grain production on a smaller scale and explore ways to make small-scale grain production viable for the small grower. This project also seeks to discover which heirloom dry bean varieties are suitable for production in Indiana.

What are dry edible beans?

Dry edible beans, or simply dry beans, are a food-grade storage grain crop. Dry edible beans are the same species as fresh edible beans (i.e., green beans or fresh shell beans), Phaseolus vulgaris. Many bean varieties are available; some can be grown for fresh or dry use. They are most commonly grown as a food-grade crop and provide many nutritional benefits to those who consume them. They can be incorporated into animal feed but are more lucrative in the food-grade market, selling for as much as $36 per bushel ($60 per hundredweight (cwt)) in the organic marketplace. Compare this to certified organic soybeans, which sold for $35-40 per bushel in 2022 and require an additional 20 days to mature.

Dry beans are a shorter-season crop, usually taking 80-90 days from planting to harvest. They prefer well-drained soil and are generally poor competitors with weeds. In organic management, dry beans require vigilance and much attention focused on mechanical weed control. Foxtails and other grasses are public enemy number one for this crop, but any weed will be problematic for growing these successfully. On the other hand, dry beans are a legume and can provide for much of their own nitrogen needs, even in soils that have relatively low organic matter, like the sandy soils where they prefer to grow. Dry beans are most commonly grown in the north-central states of the US, as well as Ontario, Canada. North Dakota is the number one producer of dry beans in the US, followed by Michigan, Nebraska, and Idaho. While these states differ in climate and weather patterns, they share some combination of suitable soil types, rainfall amounts, grain handling infrastructure, and shortened growing seasons that make growing dry beans (versus soybeans) a viable option for the commercial grain grower.

Many commercially available dry beans at the grocery store are limited to a handful of specific types. Commonly available to consumers are pinto beans, the most popular bean in the US market, black beans, great northern beans, and kidney beans. However, many dry bean varieties not readily found at grocery stores are available to small-scale growers and market gardeners. These varieties often are locally adapted to where they were bred rather than bred for adaptability to a large geographic area or mechanized harvest. In addition to local adaptability, each dry bean has specific flavor profiles, culinary characteristics, and cultural history that can help enrich the farmer’s and consumer’s kitchens while providing essential nutrients, such as fiber, protein, and several minerals, to the human diet.

Project description and design

We conducted variety trials at the Purdue Student Farm (West Lafayette, IN) and Pinney Purdue Agricultural Center (Wanatah, IN). For more details about the design of this trial, please visit the “Project” section of the Purdue Organic Agriculture website.

The research was not conducted on certified organic land, but the land has been managed organically for over six years at each site. The major difference between sites is soil type – Pinney features a well-drained sandy loam, and the Purdue Student Farm features a poorly drained silty clay loam.

The following varieties were evaluated:

- Black Coco – a type of black bean (determinate bush-type)

- Calypso – a type of black bean (determinate bush-type)

- Jacob’s Cattle – a type of kidney bean (determinate bush-type)

- Tiger’s Eye – a type of cranberry bean (indeterminate upright-type)

We selected varieties based on several characteristics, including time to maturity, cultural relevance to the Midwest, common cooking preparations, and growth habit.

We used an Earthway seeder fitted with a pea plate to plant each variety in a double row, each with about 18 inches between row centers (Figure 1). Drip irrigation was set up for each trial. At the Student Farm, shaped beds were used to help improve drainage. Both trials were planted in early-mid June and harvested by mid-September. Harvest can take place as soon as bean pods are about 85% yellow and 15% brown or when beans split in two when hit with a hammer.

To prepare dry beans for sale must be threshed and winnowed. We used two threshing methods to develop recommendations and materials for future demonstrations. 1. Manual threshing was completed by flailing bean plants against the inside of a 55-gallon food-grade plastic drum (Figure 2). 2. Mechanical threshing was done using a Swanson Machine Co. portable gas-powered plot thresher (Figure 3).

Each method presented advantages and disadvantages.

- Time commitment – hand threshing took as much as ten times longer, especially with only one person.

- Expenses devoted to purchasing and maintaining a machine – threshing machines can cost upwards of a few thousand dollars.

Whether threshed mechanically or manually, all dry beans still needed to be winnowed. Winnowing can be done using mesh screens or moving air to separate dry biomass from the beans. In this case, moving air (garage fan) was used to help simulate conditions and equipment available to a small-scale grower. Video footage was procured from this process further to instruct prospective growers (available upon request). Part of the process is shown below.

Preliminary Results

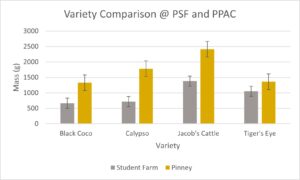

Dry beans were weighed by replicate in grams after complete threshing and winnowing (Figure 4).

Figure 4. Comparison of average mass (g) produced by each variety in each replicate at PSF (gray) and PPAC (gold).

This preliminary data provides insight for future years. One of the significant differences in performance between the two field sites was the yield of Calypso. Calypso performed poorly at the Purdue Student Farm. The increased production at Pinney may signal a strong response to well-drained soil conditions at Pinney versus poorly drained conditions and weed pressure at the Purdue Student Farm. The only other insight worth discussing is the strong performance of Jacob’s Cattle at both locations.

Thank you to North Central SARE for the financial support of this project!