The last two summers, I have had pretty good fungicide trials for powdery mildew of pumpkin. Since all of the products trialed are now labeled or close to being labeled, I thought it was time to share this information with vegetable growers of Indiana.

First, a bit of background about this disease. In Indiana, powdery mildew affects primarily pumpkin and cantaloupe. The disease is easily recognized by the talc-like lesions on both sides of the leaf. (This article will help with diagnosis.) If left uncontrolled, the disease can cause loss of foliage, loss of yield and lower quality fruit.

The fungus that causes powdery mildew, Podosphaera xanthii, does not require leaf wetness for infection of leaves, only high humidity. The optimum temperature for disease development is 68 to 81°F. P. xanthii may survive in crop residue as a resilient fungal structure, but the disease is so easily windborne, that crop rotation is not always a practical control measure.

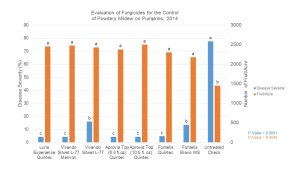

Figure 1: Fungicide pumpkin powdery mildew trial conducted at the SW Purdue Ag Center in 2014. Blue bars represent powdery mildew disease severity in percent. Orange bars represent yield in numbers. Bars of the same color with the same lettter are not significantly different (alpha=0.05, LSD).

Fortunately, commercial varieties of pumpkin and cantaloupe exist with partial resistance to powdery mildew. Most growers, however, find it necessary to apply systemic fungicides to manage powdery mildew, even when using partially resistant varieties. The two trials I describe below use a susceptible variety of pumpkin, Gold Challenger, to assure plenty of disease.

In 2014, all of the fungicides used resulted in significantly less powdery mildew than the untreated check (Figure 1). Fontelis alternated with Bravo Weather Stik® and Vivando® used alone (Silwett is a wetting agent) did not control powdery mildew as well as any of the other fungicide treatments. The best fungicide treatments were Luna Experience® (check to see whether Luna Experience® is labeled on cantaloupe and pumpkin-this label is due to be announced any day) alternated with Quintec® , Vivando® alternated with Merivon®, Aprovia Top® at 8.5 fl. oz per acre alternated with Quintec®, Aprovia Top® at 10.5 fl oz. per acre alternated with Quintec® and Fontelis® alternated with Quintec® (no statistical difference between these treatments). The untreated check had significantly fewer pumpkins than any of the fungicide treatments.

The primary lessons for the 2014 trial may be summarized as follows:

- Untreated, powdery mildew may cause loss of yield in pumpkins, at least with susceptible varieties.

- While Bravo WS®, common name chlorothalonil, is useful against a broad range of diseases as a preventative fungicide, this product is not systemic. Therefore, it is not a good rotational product for powdery mildew.

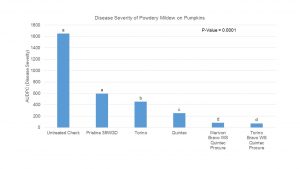

In 2015, the untreated check had more powdery mildew than any other treatment except for Pristine® (Figure 2). This may indicate that the powdery mildew fungus has developed resistance to the two active ingredients in Pristine®: pyraclostrobin, FRAC group 11, and boscalid, FRAC group 7 (FRAC stands for Fungicide Resistance Action Committee. Each FRAC group represents a different fungicide mode of action.)

Figure 2: Fungicide trial for pumpkin powderty mildew conducted in 2015 at the SW Purdue Ag Center. Bar represent powdery mildew disease severity in AUDPC (Area Under the Disease Progress Curve). Bars with a different letter are not signficantly different (alpha= 0.05 LSD).

The next step down for fungicide efficacy in the 2015 trial, was Torino® (used alone) which had significantly better control than Pristine®, but not as effective as any of the other treatments. Quintec® used alone was better than Torino®, but not as good as the two remaining alternations.

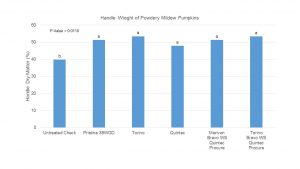

The treatments that resulted in the least amount of powdery mildew in 2015 included either Torino® or Merivon® alternated with Quintec® and Procure® (Bravo WS® was tank mixed with Merivon®, Torino® and Quintec®). There were no yield differences in 2015, however, there was some interesting differences in handle quality due to powdery mildew severity (Figure 3). At harvest, approximately 4 inches of the stem next to the fruit (the handle) were removed, weighed and dried for 48 hours at 110°F and weighted again. From this data the percent dry matter in the handles were calculated. There was no difference in percent dry matter in pumpkin handles between fungicide treatments. However, the untreated check had a lower dry matter percent than any of the fungicide treatments. Presumably, the reason percent dry matter was less in the untreated check is that powdery mildew caused fewer carbohydrates (photosynthates) to be translocated from the leaves to the handles.

Figure 3: Fungicide trial for pumpkin powderty mildew conducted in 2015 at the SW Purdue Ag Center. Bar represent dry matter percent in pumpkin handles. Bars with a different letter are not signficantly different (alpha= 0.05 LSD).

The take home for the 2015 trial could be summarized as:

- Pristine® may not be an effective management tool for powdery mildew of cucurbits in Indiana anymore.

- The best fungicide treatments may be those that alternate fungicide modes of action such as the two in 2015 that utilize Torino® or Merivon® with Quintec® and Procure®.

- Even if yield is not directly affected by powdery mildew, fruit or handle quality may be affected as observed in this study.

Although Quintec® is not a systemic product, this product may become redistributed around the leaf by vapor action. This product, in a proper alternation with other products using a different FRAC code, has proven to be effective. Merivon®, a relatively new product with a novel mode of action, appears to be effective for powdery mildew plus it is labeled for other diseases as well. Torino® appears to be a good powdery mildew product if alternated with another product.

For experimental purposes, not all treatments described here alternate fungicides with different FRAC groups or MOA’s. However, growers should know the FRAC groups for each of their fungicides and plan on a fungicide alternation between FRAC groups. Such an alternation will help to reduce the chance of creating fungi with resistance to one or more FRAC groups. Plus, as seen here, alternating between fungicide FRAC groups often results in better disease control.

For further information, contact the author or the Midwest Vegetable Production Guide for Commercial Growers (the 2016 version is now on-line).

This article also appears in the blog veggiediseaseblog.org.