I often receive questions on how much water should apply to high tunnel tomatoes. Even the most experienced tomato growers could sometimes lose yield because of overlooking irrigation management. In this article, I describe a case study of how we use soil moisture sensors for irrigation management in a high tunnel tomato production system. This irrigation schedule is not likely to apply to all situations. Still, I hope the general trend and how we make decisions could help tomato growers be more comfortable in irrigation management.

This project is conducted in a high tunnel at Southwest Purdue Ag Center in Vincennes, IN. The soil is sandy with less than 1% organic matter. We planted six rows of tomatoes in a high tunnel on black plastic-covered beds with one drip tape for each bed; the tomato rows are about 65 feet long. Eight tomato cultivars, including six slicer tomatoes and two cherry tomatoes, were transplanted on Apr. 13, 2023. The flow rate of the drip tape is 0.67 gpm/100’. The total length of drip tape for the tomato beds is about 400’.

The beds were well irrigated at transplanting. In the first three weeks after transplanting, we irrigated the plants only when we felt the top soil was dry. At this point, we feel comfortable irrigating by feeling because the roots are shallow, and we can tell soil moisture levels at the root zone. Small plants do not need much water, and relatively cool weather in the early season changes soil moisture levels slowly.

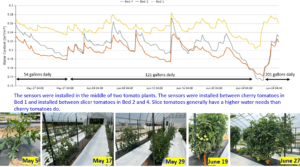

We started automatic irrigation control in the first week of May and set the irrigation program for 10 mins at each event twice daily. The program applied 54 gallons of water daily to the tomatoes. On May 24, we installed soil moisture sensors measuring volumetric water content in three beds at 12’’ soil depth inside the high tunnel.

The water content at the 12-inch depth declined from 0.23 to 0.18 cm3/cm3 from May 24 to May 31, although the system applied 54 gallons of water daily. The sensor readings raised the alarm that we were short irrigating. We then changed the irrigation program to three daily irrigation events and 15 mins for each event. The new schedule applied 121 gallons of water daily to the tomato plants. The soil water content at the 12-inch depth was maintained between 0.18 to 0.24 cm3/cm3 until around June 23. After June 23, we no longer see the soil moisture content respond to irrigation events. The water content constantly dropped to around 0.14 cm3/cm3. Again, the readings raised the alarm that we were short on irrigation. We adjusted the program again and set up irrigation for four events for 20 mins each on June 27. The new schedule now applies 201 gallons of water daily to the system.

So far, we have been adjusting irrigation based on soil water content. When the readings started to decline, we increased the irrigation amount. But how do we decide how much to increase? We need a good idea of how much water the plant needs to answer this question. An excellent way to estimate plant water needs is to use the reference crop evapotranspiration method (ETc = ETo × Kc). This publication describes the method in detail. Assume ETo = 0.2 (in.) on a sunny summer day, and Kc = 0.9 at full plant growth, then ETc = 0.2 × 0.9 =0.18 (in.). You may have heard that most fruiting vegetables require 1-1.5 inches of water per week at peak production. The above calculated number times seven is where the 1-1.5 inches come from.

The next question is what the 0.18 (in.) mean for the tomato system? I included my calculation below, which leads to 224 gallons of water per day.

0.18 x (400 X 5 / 43560) X 27154 = 224 gallons per day (400 feet is the total bed length; 5 feet is the spacing between beds; 1 acre =43,560 ft2; 1-inch acre = 27,154 gallons)

Our current irrigation program is applying slightly less amount of water daily compared to this number. We are at the beginning of harvest. The plants look healthy and loaded with fruit. We have not seen tomato blossom end rot, indicating we have been doing an adequate job in irrigation management.

Here are a few take-home messages from this case study:

1. Soil moisture sensors are a great tool to guide irrigation management, especially for high tunnel production. Reliable soil moisture sensors and timely data access are indeed expensive investments, but seeing soil water content change at a depth that is hard to reach by hand is critical for timely irrigation adjustment and avoiding yield loss. However, be aware that soil moisture sensors may not always work nicely as we expected. We will write another article to share our experience using soil moisture sensors and what could go wrong that affect our decisions.

2. Combined use of soil moisture sensors and evapotranspiration method provides a more comprehensive picture than using each method alone. As stated above, soil moisture sensors tell us the soil conditions responding to the irrigation application, which help us make timely adjustment to the irrigation schedule. Evapotranspiration gives us a general idea of plant water needs at different growth stages. It can serve as a guide on how much we should increase or decrease the irrigation amount.

3. The plants grow vigorously, have large canopies, and have a lot of fruit sets. All these factors make us confident that the plants are at their highest water need for the particular growth stage. However, the water need should be adjusted accordingly if plants suffer disease, insect pests, or plant growth is stunted because of environmental stresses.

4. In this study, the soil is sandy with good drainage, and we do not have concerns about diseases often associated with wet soil, so we feel comfortable applying water to meet plants’ needs. One should be more cautious in irrigation management if certain soilborne diseases are present.

5. This project did not consider soil wetting patterns and how the irrigation design affects nutrient management. These articles, Water Affects Efficacy of Soil-incorporated Fertilizers and Amendments and Understanding Wetting Patterns in Drip Irrigation, provide insights into these questions.

Please do not hesitate to contact me, Wenjing Guan (guan40@purdue.edu), if you have questions or need further discussion.

Funding for the project Improve Drip Irrigation Management for Vegetables and Melon Production in Indiana was made possible by the Indiana State Department of Agriculture through grant A337-22-SCBG-21-003. Its contents are solely the responsibility of the authors and do not necessarily represent the official views of the ISDA.