Several weeks ago, Indiana received enough rain to eliminate drought across the state, leaving behind just a few counties in Abnormally Dry (D0) status. Fortunately, this week has been relatively quiet, allowing many areas to alleviate flooding issues. The U.S. Drought Monitor kept those Abnormally Dry areas nearly the same this week (Figure 1), so[Read More…]

Vegetable Crops - General

Under waterlogging conditions, oxygen depletion in the soil injures roots, limiting their ability to uptake nutrients and water. In response, plants close their stomata to prevent water loss, leading to a subsequent reduction in photosynthesis. Common symptoms include wilting, stunted growth, and yellowing leaves. If the stress persists for an extended period, plants may eventually[Read More…]

Common names: Ground ivy, gill-over-the-ground, creeping Charlie, field balm, haymaids, cat’s foot, alehoffs Latin name: Glechoma hederacea L. Family: Lamiaceae (Mint Family) General Description and Identification Ground ivy is a perennial herbaceous plant that creeps along the soil surface and thrives in moist and shady areas (Figure 1). It was introduced to the US from[Read More…]

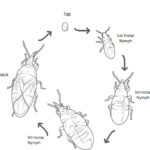

Orius insidiosus, also known as the minute pirate bug, is native to North America and a beneficial insect (Figure 1). They are generalist omnivores, feeding on other insects and pollen. Minute pirate bugs belong to the Order of true bugs — Hemiptera — in the family Anthocoridae. Orius insidiosus can be found in a wide range[Read More…]

Harvest season is easily one of the busiest and craziest times of the year. Crops are being harvested, packed, shipped, and sold against a backdrop of perishability, weather, and ever-changing markets. Harvest and postharvest handling are also critical times for food safety. Handling of the crop by workers, transporting of produce, and aggregating the crop[Read More…]

Welcome to the Vegetable Crops Hotline (VCH), Purdue Extension’s exclusive newsletter for people in the business of growing vegetables. The past two weeks were packed with field days. The Purdue Fruit and Vegetable and the Purdue Small Farm Education field days were well attended, 90 and 73, respectively. This issue includes our insect and weed[Read More…]

Time is running out to register for the annual Purdue Small Farm Education field day! July 25, 2024, at the Purdue Student Farm, West Lafayette, IN. The deadline to register is July 22nd at 12:00 p.m. ET. Register here: Purdue Small Farm Education Field Day The program is now available. Download HERE. SF2024_FIeldDay_Demo_Schedule SF2024_FIeldDay_Demo_Descriptions Contact[Read More…]

Time is running out to register for the annual Fruit and Vegetable Field Day July 18, 2024, at the Throckmorton/Meigs Horticulture Farm, Lafayette, IN. Registration ends on July 15th at 12:00 p.m. ET. Register here: Purdue Fruit and Vegetable Field Day The program is now available. Download HERE. Fruit and Veg Field Day 2024_Agenda FINAL_page1[Read More…]

The Clearspring Produce Auction is located just 2 miles south of US 20 in Clearspring Township in the Heart of the LaGrange-Elkhart Amish Settlement. It is within easy driving distance of the towns of Shipshewana, Topeka, Emma, and LaGrange. Produce is sold 3 days a week throughout most of the growing season (Tuesday, Thursday, Friday),[Read More…]

Thrips, aphids, planthoppers, leafhoppers, and whiteflies are common pests of specialty crops that are often misidentified. Whether it’s tomatoes or squash, it’s important to know the differences between these insects and what it means to see them on or around your crops. Below, we provide some information and diagnostic tips to identify each of these[Read More…]